Robotics in US Manufacturing: Boosting Factory Efficiency

Robotics plays a crucial role in enhancing manufacturing efficiency in US factories by automating tasks, improving precision, and reducing operational costs.

The integration of robotics into manufacturing processes is rapidly transforming industries across the United States. Discover how the adoption of robotic technologies is not only improving efficiency but also reshaping the future of US factories, making them more competitive and innovative. This article explores the multifaceted impact of The Role of Robotics in Manufacturing: Improving Efficiency in US Factories.

The Rise of Robotics in American Manufacturing

The American manufacturing sector has witnessed a significant shift towards automation, driven primarily by the need for increased efficiency and precision. Robotics, once a futuristic concept, is now a cornerstone of modern manufacturing, playing a vital role in streamlining processes and enhancing productivity.

This transformation is not merely about replacing human labor; it’s about optimizing workflows and creating a more agile and competitive industrial landscape. Let’s delve into the factors driving this robotic revolution and its implications for US factories.

Key Drivers of Robotic Adoption

Several factors contribute to the increasing adoption of robotics in American manufacturing. Here are some of the most significant drivers:

- Increased Production Speed: Robots can perform tasks faster and more consistently than humans, leading to higher output rates.

- Improved Precision and Quality: Robotic systems minimize errors and ensure consistent quality, reducing waste and improving product reliability.

- Reduced Operational Costs: While the initial investment can be substantial, robots can significantly reduce long-term labor and operational costs.

- Enhanced Workplace Safety: Robots can handle hazardous tasks, protecting human workers from dangerous conditions.

These advantages make robotics an increasingly attractive option for manufacturers seeking to enhance their competitiveness and adapt to evolving market demands. As technology continues to advance, we can expect even wider adoption of robotic solutions across various sectors of American manufacturing.

Enhancing Efficiency Through Automation

One of the primary benefits of integrating robotics into manufacturing processes is the significant enhancement of efficiency. Automation, driven by robotics, allows factories to streamline operations, reduce cycle times, and optimize resource utilization.

From assembly lines to quality control processes, robots are revolutionizing the way products are made. Let’s explore specific examples of how robotics is improving efficiency in different areas of manufacturing.

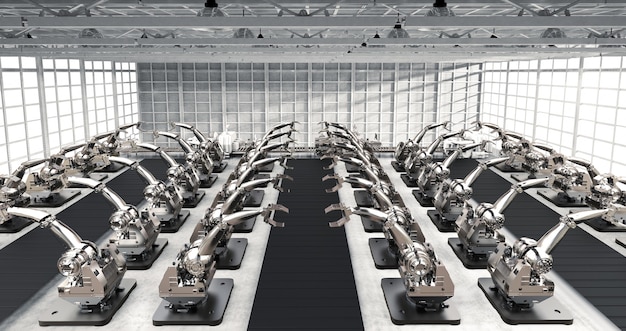

Robotics in Assembly Lines

Assembly lines have long been a staple of manufacturing, but robots are taking them to the next level. Robotic arms can perform repetitive tasks with speed and precision, reducing bottlenecks and increasing overall throughput. Additionally, robots can be easily reprogrammed to adapt to changes in product design, providing greater flexibility and agility.

Robotics in Quality Control

Maintaining high product quality is crucial for any manufacturing operation. Robots equipped with advanced sensors and vision systems can perform thorough inspections, identifying defects and ensuring that products meet stringent quality standards. This automated quality control process minimizes human error and reduces the risk of defective products reaching the market.

In summary, the integration of robotics in manufacturing is not only accelerating production but also enhancing the reliability and quality of the final products. This leads to greater customer satisfaction and a stronger competitive position for American factories.

The Impact on Labor and Workforce Development

The introduction of robotics into manufacturing inevitably raises questions about its impact on the labor force. While some fear job displacement, many experts argue that robotics can create new opportunities and transform the nature of work in manufacturing.

Instead of replacing human workers entirely, robots often augment their capabilities, allowing them to focus on more complex and strategic tasks. Let’s examine the various ways robotics is reshaping the workforce and the need for workforce development initiatives.

Retraining and Upskilling Initiatives

As robots take over routine tasks, there is a growing need for workers to develop new skills in areas such as robot programming, maintenance, and data analysis. Companies and educational institutions are increasingly offering retraining and upskilling programs to help workers adapt to these changing requirements.

New Job Creation

The robotics industry itself is creating new jobs in areas such as robot design, manufacturing, and integration. Additionally, as manufacturing processes become more efficient, companies may be able to expand their operations and create more jobs in other areas such as sales, marketing, and customer support.

The key to a successful transition is proactive workforce development, ensuring that workers have the skills they need to thrive in a rapidly evolving manufacturing landscape. By investing in education and training, we can harness the full potential of robotics while creating a more skilled and resilient workforce.

Challenges and Considerations

While the benefits of robotics in manufacturing are undeniable, there are also challenges and considerations that companies must address. These include the initial investment costs, the need for specialized expertise, and the potential for disruption to existing workflows.

Successfully navigating these challenges requires careful planning and a strategic approach to implementation. Let’s delve into some of the key challenges and considerations for companies considering robotic automation.

Initial Investment Costs

The upfront costs of purchasing and installing robotic systems can be significant, particularly for small and medium-sized enterprises (SMEs). However, companies should consider the long-term return on investment, including reduced labor costs, increased productivity, and improved quality.

Need for Specialized Expertise

- Robotics requires specialized expertise in areas such as programming, maintenance, and integration. Companies may need to hire new employees or invest in training existing staff to acquire these skills.

- Disruption to Existing Workflows: The introduction of robotics can disrupt existing workflows and require significant changes to manufacturing processes. Careful planning and change management are essential to minimize disruption and ensure a smooth transition.

- Data Security: The robots that get connected to the internet and other devices pose a danger of information and data leakage.

By addressing these challenges proactively, companies can maximize the benefits of robotics and avoid potential pitfalls. A well-thought-out implementation strategy is essential for successful adoption of robotic automation.

The Future of Robotics in US Factories

Looking ahead, the future of robotics in US factories appears bright. As technology continues to advance, we can expect to see even more sophisticated and versatile robotic systems that can perform a wider range of tasks. Artificial intelligence (AI) and machine learning (ML) are playing an increasingly important role in enhancing the capabilities of robots and enabling them to adapt to changing conditions in real time.

AI-Powered Robots

AI-powered robots can learn from experience, make decisions, and adapt to changing conditions without human intervention. This allows them to perform complex tasks with greater autonomy and efficiency. For example, AI can be used to optimize robot movements, predict maintenance needs, and improve quality control processes.

Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers, assisting them with tasks that are physically demanding or require precision. These collaborative robots are equipped with sensors that allow them to detect the presence of humans and avoid collisions, making them safe to work around. Cobots are becoming increasingly popular in industries such as automotive, electronics, and aerospace.

The future of robotics in US factories is one of increasing automation, intelligence, and collaboration. By embracing these advancements, American manufacturers can stay competitive and thrive in the global marketplace.

Case Studies: Success Stories in US Manufacturing

To illustrate the transformative potential of robotics in manufacturing, let’s examine a few case studies of US companies that have successfully integrated robotic technology into their operations. These examples showcase the diverse applications of robotics and the tangible benefits they can deliver.

- Automotive Industry: A leading automotive manufacturer implemented a robotic assembly line that reduced production time by 30% and improved product quality.

- Aerospace Industry: An aerospace company used robotic systems to automate the drilling and fastening of aircraft components, resulting in increased precision and reduced labor costs.

- A food processing company utilized robots to automate the packaging and palletizing of finished goods, leading to faster throughput and reduced manual handling.

These case studies demonstrate that robotics can be a game-changer for US manufacturers, enabling them to achieve new levels of efficiency, quality, and competitiveness. By learning from these success stories, other companies can gain valuable insights and inspiration for their own robotic automation initiatives.

| Key Aspect | Brief Description |

|---|---|

| 🚀 Increased Efficiency | Robots automate tasks, reducing cycle times and optimizing resource utilization. |

| ⚙️ Improved Quality | Robots minimize errors, ensuring consistent product quality and reducing waste. |

| 💰 Reduced Costs | Robots reduce long-term labor costs and improve operational efficiency. |

| 🧑🏭 Workforce Development | Retraining and upskilling initiatives needed to adapt to changing job requirements. |

Frequently Asked Questions (FAQs)

▼

Robots enhance efficiency by automating repetitive tasks, increasing production speed, and minimizing errors, leading to higher output and consistent quality.

▼

Key challenges include high initial investment, the need for specialized expertise, and potential disruption to existing workflows during the transition.

▼

Robotics often leads to a shift in job roles, requiring workers to develop new skills in programming, maintenance, and data analysis rather than routine tasks.

▼

AI and machine learning enhance robot capabilities, enabling them to learn from experience, make autonomous decisions, and adapt to changing conditions in real-time.

▼

Cobots are designed to work safely alongside human workers, assisting with physically demanding or precision-oriented tasks, enhancing overall productivity.

Conclusion

In conclusion, the integration of robotics in US factories is a transformative trend that promises to drive significant improvements in efficiency, quality, and competitiveness. By addressing the challenges and embracing the opportunities presented by this technology, American manufacturers can position themselves for success in the global economy.